Gravity Flat

Easy handling

compact design

fast and high-quality engraving

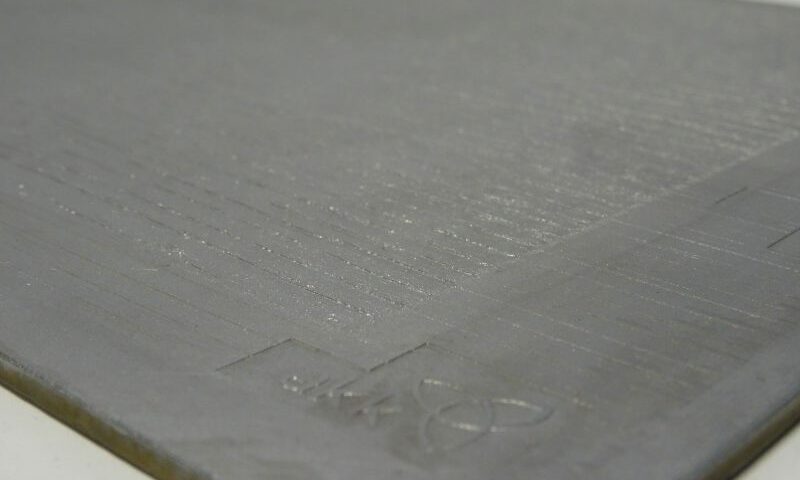

With the Gravity Flat, embossing plates can be produced quickly and precisely in multiple stages. A liquid, etch-resistant medium is heated with a high-resolution multi-jet spray head and partially jetted onto the embossing plate at up to 12 m²/h. Noses, errors or gradients? Not a chance! The print drop solidifies as soon as it hits the medium. Only a finely defined printing dot remains on the plate. The plate is then etched and cleaned before the next layer is applied.

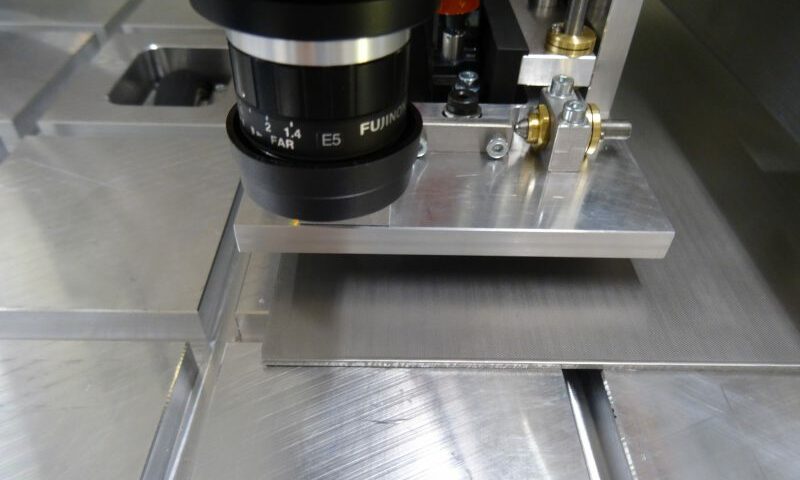

Design transfers of up to 1,440 dpi are no problem here, nor are multiple etchings. This is because the plates can be clamped into the machine several times in the exact position using a camera system. The mechanics of the vacuum table can be moved with an accuracy of a few micrometers, so that even large panels can be positioned easily, quickly and accurately.

Our expertise is impressive: almost all leading manufacturers worldwide use our system technology. There are often even several systems in operation in one plant. The respective machine size can be adapted to individual customer requirements.

Fields of application

Embossing industry, press-plate industry, HPL panel industry, leather industry, glass industry

Technology

- Konica Minolta Printhead

- 1.440dpi resolution

- Dimatix Printhead

- 1.100 dpi resolution

Vorteile

- Cost-effective and efficient production

- High-resolution print quality

- Optimisation of processes

- Consistent quality at every production site

- Fast engraving times of up to 12 m²/h

- Machine sizes from 1 m x 1 m up to 8 m x 3 m

Contact

Are you interested in this product and would like personalised advice? I will be happy to contact you directly.

Peer Kesper

Get in touch

Our products are individually adapted to the needs of the respective customer application and seamlessly integrated.

- All products available made to measure

- Use of fiber laser technology

- Use of high-resolution exposure units

- Individual designs

- High-precision laser components and systems