Gravity Mold

Easy handling

compact design

fast and high-quality engraving

When it comes to Gravity Mold, our success proves us right: more than 75 of these engraving machines are already in use by our customers worldwide. Why? It allows molds to be produced in a digital, efficient process. In a quality that always remains the same – wherever in the world the machine is used.

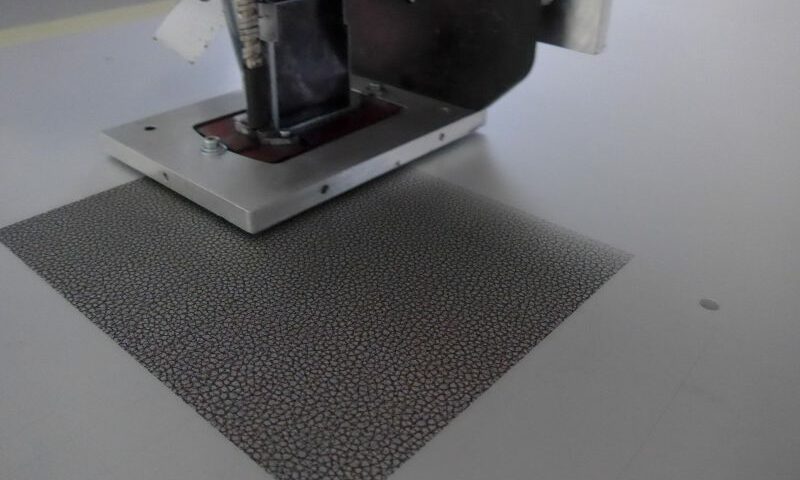

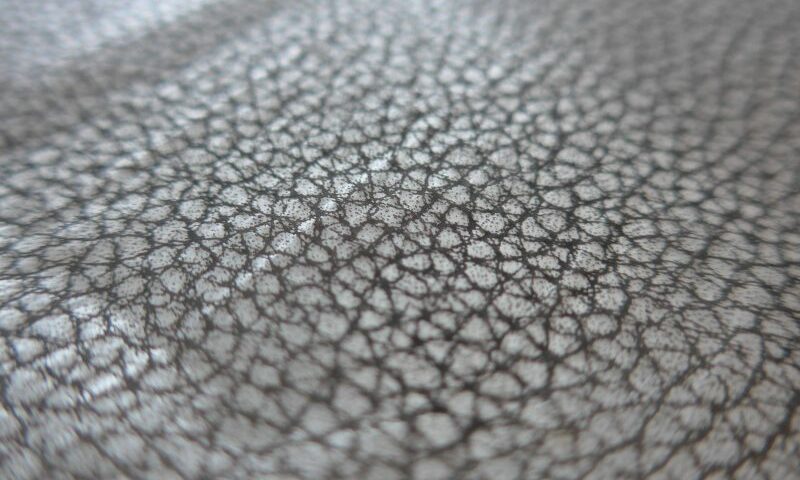

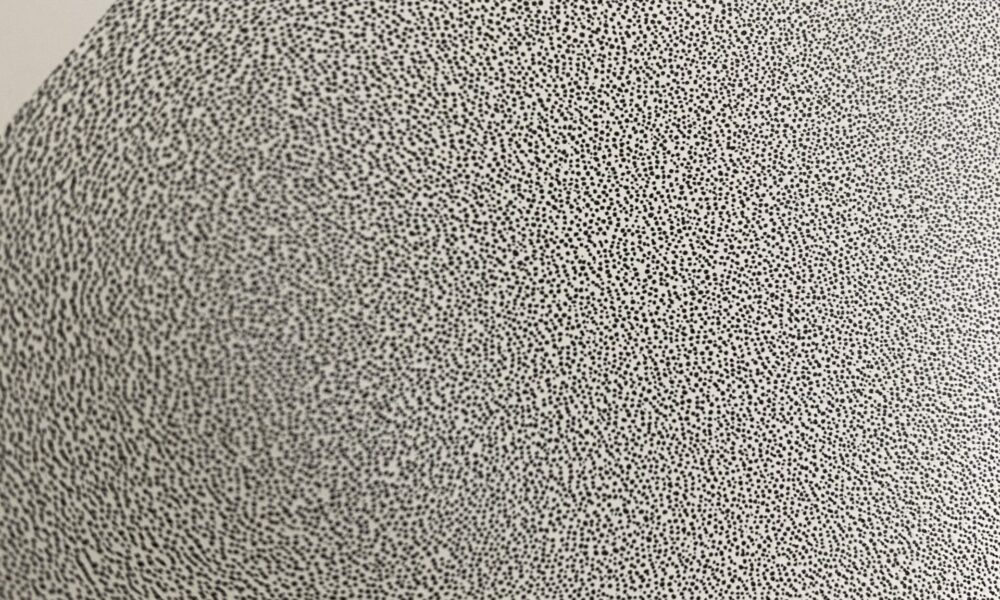

Design transfers of up to 1,440 dpi are possible with the Gravity Mold. To do this, the machine heats a liquid, etch-resistant medium to 85 to 125 degrees Celsius using a high-resolution multi-jet spray head and sprays this partially onto a film or paper. In a sophisticated transfer process, the film is then inserted into the mold with the printed side facing down and rubbed off. The mold can then be etched at 40 to 45 degrees Celsius.

Our proprietary wax paste not only provides excellent adhesion and transfer properties.

The Gravity Mould is available as a rotary drum machine in all sizes.

All global texturing companies rely on AkK technology. Even for newcomers to this technology, our Gravity Mold is a very economical solution for setting accents and growing in this area.

Areas of application

Furniture industry, automotive industry, toy industry, packaging industry

Technology

- Konica Minolta printhead

- Dimatix printhead

- 1.100 dpi – 1.440 dpi resolution

Advantages

- High productivity

- High-resolution print quality

- Optimisation of processes

- Consistent quality at every production site

- Independent use of film and paper

- Easy operation and maintenance

Contact

Are you interested in this product and would like personalised advice? I will be happy to contact you directly.

Peer Kesper

Get in touch

Our products are individually adapted to the needs of the respective customer application and seamlessly integrated.

- All products available made to measure

- Use of fiber laser technology

- Use of high-resolution exposure units

- Individual designs

- High-precision laser components and systems